For certain products, temperature and humidity are of the utmost importance during manufacture, transport, and storage. In industries related to healthcare, pharmaceuticals, and food and beverages, understanding and managing these environmental components are key. Keeping products in areas with the correct thermal (temperature and humidity) conditions is necessary to ensure their integrity and that all regulations are met. This is where thermal mapping comes in.

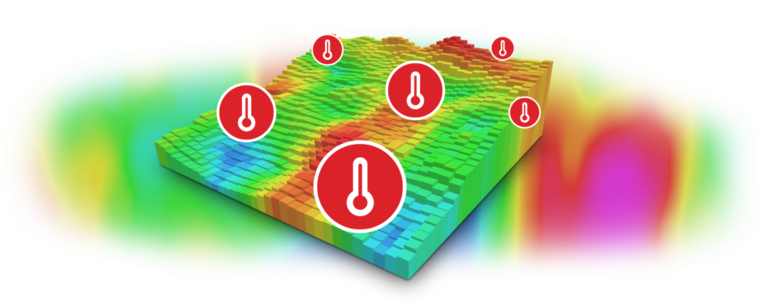

Temperature mapping, or thermal mapping, is a process that goes a step beyond simple monitoring of environmental conditions. Using multiple data loggers, thermal mapping creates a comprehensive “map” of an area so that exact thermal conditions can be known as they are occurring in the space at all times and under all circumstances. Here are factors for which the practice of thermal mapping is important.

Protecting your products and consumers

The integrity of the products for which your company is responsible is the most important reason for thermal mapping. In industries such as the ones mentioned earlier, the temperature and humidity in the areas where certain products are produced, transported or stored is absolutely critical. Even in controlled spaces that are well monitored for thermal fluctuations, unless you have a comprehensive picture of what occurs in every area of the space under multiple types of conditions, your company is not fully prepared to meet regulatory standards.

Not understanding the thermal makeup of controlled spaces can do an incredible amount of damage. If a product is rendered unusable because of fluctuations in thermal conditions within a controlled space, that product may have to be destroyed, costing the company millions of dollars. Perhaps even worse than having to destroy products is putting a product on the market that is potentially dangerous to consumers. No company wants to produce dangerous products for any number of moral, ethical, public relations and financial reasons. If a harmful product is brought to market and consumers get sick or worse, the consequences and punishments for that company can be devastating.

With thermal mapping, any company can know what happens to the temperature and humidity during optimal conditions and, maybe more importantly, in suboptimal ones. What happens when you open the door to the refrigeration unit? How long can a space maintain temperature if the power goes out? How are internal thermal conditions affected by outside conditions? Thermal mapping helps answer these questions to keep products and consumers safe.

Achieving and maintaining regulatory compliance

The federal government sets up strict rules and regulations for industries related to healthcare and consumable goods to make sure that no one is injured by the mishandling of products. The United States regulatory body for these matters, the Food and Drug Administration (FDA) has some of the strictest standards in the world when it comes to the handling of drugs and food.

Thermal mapping can ensure that your company is always on the right side of the FDA or any other regulatory body. With the constant monitoring thermal mapping brings to such areas as maintenance of required low temperatures in freezers and refrigeration units or the mandated high temperatures in ovens or in processes such as sterilization, you can be assured your temperature and humidity controlled areas are compliant at all times.

When regulatory inspectors visit a facility, they don’t rely on your monitors, they bring their own testing equipment with them. Thermal mapping gives you the assurance that your facility is maintaining conditions that meet regulatory compliance and will pass inspections. With it, you know exactly what happens on any given day in every area of your controlled space. No matter where the inspector goes, you will have the peace of mind that all areas are up to code.

Understanding the impact of your HVAC systems

Thermal mapping does not only give you a more comprehensive picture of the temperature and humidity of your space or equipment. It also tells you about the performance (or shortcomings) of your heating, ventilation, and air conditioning (HVAC) systems. You can think of thermal mapping as a stress test for your HVAC system.

Thermal mapping is accomplished with multiple data loggers in all areas of your controlled space over a specific period of time. To create a full thermal map, you need to gather temperature and humidity data during all sorts of conditions. You will have to take into account conditions when the space is empty vs. full, door open vs. closed, hot and humid days vs. cold and dry days, and instances of the HVAC system running at full capacity vs. situations where the power goes out or conditions cause the HVAC system to break down.

Gathering all this information while creating a thermal map will help you better understand exactly what your HVAC system’s capabilities are and what you may need to upgrade or do differently. You may even find that you do not need as much power to your systems to meet production needs, thereby saving your company money over the long-term.

Determining your monitoring needs

Thermal mapping is not the same thing as simply monitoring a space for temperature and humidity. If performed correctly and thoroughly, thermal mapping is an important first step when setting up your monitoring practices in order to keep your products safe and to stay compliant with regulations.

As Dickson notes, thermal mapping is both rigorous and complex. It paints a complete picture of what is happening with the thermal conditions in your space at all times and in every area. Once you have completed the process of thermal mapping, you will be much better prepared to create a monitoring plan that will be effective for your needs.

A thermal map shows hotspots, cold spots, and when conditions indicate that you may have a problem maintaining a certain temperature and humidity level. This data will help you create monitoring procedures that will not only help confirm what you already know but also truly keep an eye on possible problem areas. The results of mapping can help you understand where to place or move sensors or put standard operating procedures (SOPs) in place to ensure that, when conditions dictate, certain areas are being more strictly monitored. Starting with a proper thermal map makes long-term monitoring much more effective and efficient.

Conclusion

Humidity and temperature mapping are vital to companies and industries for which the conditions under which a product is created, transported, or stored are important. This type of mapping uses real-time data to help you understand exactly what conditions are so that you can keep your products safe to use, stay compliant with regulations, test your HVAC capabilities, and consistently monitor your spaces over time. Without creating a thermal map, you simply will not have enough data to fully understand conditions in your controlled spaces.

Leave a Reply: